Vapour Degreasing Solvents - Innovation driven by legislation

Chlorinated hydrocarbons have historically been the solvents of choice for condensation cleaning. Compatible with most materials, stable in use, producing a non-flammable saturated vapour heavier than air at a temperature greater than ambient. Traditional solvents such as trichloroethylene exhibited all these characteristics but concerns about its carcinogenic properties and the danger to operators by exposure, led to a continuing search for a safer alternative. 1,1,1 trichloroethane based solvent formulations became popular in the last century as a safer replacement. Although safer for users, it proved to be depleting the ozone layer and was subsequently banned.

In Europe, the United States and in other advanced economies increasingly stringent legislation to control emissions of VOCs, especially solvents, has led to new coating formulations where water replaces most of the solvent. In the early days the quality of water-based paints was not as good as traditional solvent-based coatings, but innovation has driven the development of new polymers with results as good as the solvent-based originals.

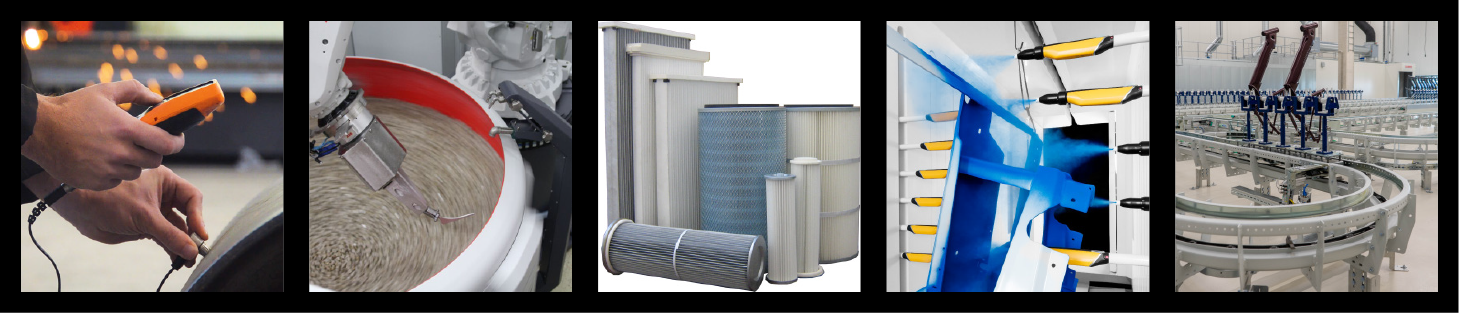

As with coatings, cleaning systems have had to change. With increasingly demanding standards of cleaning required, solvents are often the first choice, but these chemicals have been targeted by regulators and alternatives are encouraged by authorities and law makers. Water-based cleaning has many disadvantages compared to solvent-based condensation cleaning. It requires multiple heated tanks for immersion or spray processing or long programmed cycles in batch machines for cleaning, rinsing, and drying.

The process is slow, energy intensive and occupy more floor space than solvent-based equivalents where only one tank with a small footprint is needed.

Equipment and solvent must work together, so it is advisable to ensure that the suppliers co-operate to offer a package with high levels of responsible care ensure the best and safest installation.

The ideal cleaning process would be “Condensation Cleaning”, delivering shorter process times and, most importantly for the environment, using minimal energy. This process gives the highest levels of economical cleaning with minimum energy usage, low footprint on the factory floor, safety for the operator, and high production rates with low solvent usage and environmental impact. With the new generation of sealed cleaning machines its future as the process of choice is assured.

Near Zero OPD and GWP solvent blend for high performance vapour degreasing EnviroTech Europe have been supplying vapour degreasing solvent formulations for over 20 years, constantly responding to increasingly stringent regulatory requirements for environmental and safety laws and the need for improved cleaning standards. EnviroTech Europe staff and distributors are trained to work with equipment suppliers to advise on the use of vapour degreasing solvents for the most satisfactory outcome.

ProSolv®5408e is a new sustainable solvent blend with near zero Ozone Depletion Potential and Global Warming Potential for high performance degreasing and cleaning which ticks all the boxes and is the perfect profile for a modern vapour degreasing solvent. Soft on the environment, safer for users and with improved cleaning at lower costs. Lower boiling point, economical with energy, low solvent losses, faster production, easy handling.

Exceptionally low surface tension to penetrate micron sized holes and close contact surfaces. Sustainable and secure for the future.

FURTHER INFORMATION

ProSolv®5408e vapour degreasing solvent manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide.

Please visit our website https://www.envirotech-europe.com for information about all our products and further information on ProSolv®5408e.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form.